Computer Controlled Waves Energy Unit

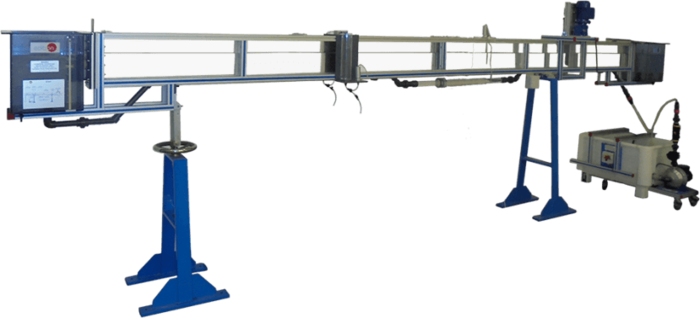

The Computer Controlled Waves Energy Unit, “EOMC”, is a unit in scale, designed to study the wave energy and the influence of several variables. The unit consists of a Base Service Unit and Waves Generator “EOMC-UB” and several Modules to be used with the “EOMCUB”, which allow to study the conversion from the waves energy into mechanical energy.

The Base Service Unit and Waves Generator “EOMC-UB” is common for the Energy Generation Modules, “EOMC” type, and can work with one or several modules. This unit mainly consists of a flow channel and a waves generator: The flow channel consists of a rectangular section with transparent walls through which water is made to circulate. Water is taken from the storage tank by means of a hydraulic pump (computer controlled) and it is driven to the inlet tank through the pipe, where the flow is quietened. Afterwards it circulates through the channel that discharges in the reception tank, returning finally to the storage tank. Thus, the closed circuit is complete. A waves sensor situated on the flow channel allows to measure the height and the frequency of the waves.

To regulate the water flow through the channel, there is a regulation valve at the output of the pump. A flow sensor is situated in the pump outlet to measure the water flow. A differential pressure sensor is used to measure the pressure drop in the orifice plate or in the Venturi tube situated in the water outlet of the pump.

The waves generator produces different types of waves. It is based on a blade that pulls the water, producing the waves. The waves frequency is modified by changing the blade rotating speed. The blade rotating speed can be regulated (computer controlled). The waves size changes according to the displaced amount of water. The amount of water displaced is modified by changing the water level

in the tank or adjusting the blade in order to introduce it deeper into the channel. A speed sensor measures the blade rotating speed.

There are several Energy Generation Modules to be used with the “EOMC-UB”:

- EOMC-1. Floating Buoy Module.

- EOMC-2. Oscillating Water Column Module.

- EOMC-3. Pelamis Module.

- EOMC-4. Tapered Channel Module.

- EOMC-5. Salter's Duck Module.

The EOMC-1, EOMC-2, EOMC-3 and EOMC-5 modules include a double acting water pump, able to extract a variable amount of water due to the up thrust of the wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a support. The amount of water collected over a number of wave cycles can be measured. They include two pressure sensors to measure the water height in the reservoirs and two flow sensors to measure the impelled water flow by the Modules.

This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board + Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

With this unit there are several options and possibilities:

- Main items: 1, 2, 3, 4, 5, 6 and 7.

- Optional items: 8, 9, 10, 11, 12 and 13.

Let us describe first the main items (1 to 7):

1. EOMC-UB. Base Service Unit and Waves Generator:

Metallic structure and panels made of painted steel.

Main metallic elements made of stainless steel.

Diagram in the front panel with similar distribution to the elements in the real unit.

Flow channel:

Channel of rectangular section with transparent

walls. It is assembled on supports, with a system

to control the inclination of the channel. Channel

slope: adjustable.

Section: 80 x 300 mm.

Length: 5 m.

Inlet tank (capacity: 38 l.), with flow stilling and drain valve.

Reception tank (capacity: 38 l.), with drain valve.

Elevation angle: each cm in the scale corresponds to 0.18º, the

maximum elevation angle is 3º.

Flow control valve.

Pipes.

Storage tank:

Capacity: 140 l., approx.

Impulsion pump, computer controlled:

Power: 0.37 kW. Max. flow: 80 l./min. Max. pressure: 20.1 m.

ON/OFF safety switch.

Manometric panel:

Formed by two PMMA pipes of 1000 mm of length mounted on an aluminium frame.

Orifice plate:

Material: PVC. Inner diameter: 80 mm.

Venturi tube:

Material: PMMA. Length: 180 mm.

Larger section: 32 mm. Smaller section: 20 mm.

A waves generator, computer controlled, to produce different types of waves. The waves frequency is

modified by changing the blade rotating speed.

Two reservoirs to collect and measure the impelled water flow by the Modules (EOMC-1, EOMC-2, EOMC-

3 and EOMC-5).

Flow sensors:

One sensor for the “Base Service Unit and Waves Generator” to measure the flow at the pump outlet,

range: 2-150 l./min.

Two sensors for the “Energy Generation Modules” to measure the impelled water flow by the Modules.

These sensors calculate the flow from the water height in the reservoirs. These water heights are measure

by two pressure sensors, range: 0-300 mm. w.c.

A differential pressure sensor for the “Base Service Unit and Waves Generator” to measure the pressure drop

in the orifice plate and the Venturi tube, range: 0-1 psi.

A waves sensor for the “Base Service Unit and Waves Generator”. This sensor allows to measure the

frequency and the amplitude of the waves generated by the waves generator.

A speed sensor to measure the blade rotating speed of the waves generator.

The complete unit includes as well:

Advanced Real-Time SCADA.

Open Control + Multicontrol + Real-Time Control.

Specialized EDIBON Control Software based on Labview.

National Instruments Data Acquisition board (250 KS/s , kilo samples per second).

Calibration exercises, which are included, teach the user how to calibrate a sensor and the

importance of checking the accuracy of the sensors before taking measurements.

Projector and/or electronic whiteboard compatibility allows the unit to be explained and

demonstrated to an entire class at one time.

Capable of doing applied research, real industrial simulation, training courses, etc.

Remote operation and control by the user and remote control for EDIBON technical support, are

always included.

Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

Designed and manufactured under several quality standards.

Optional CAL software helps the user perform calculations and comprehend the results.

This unit has been designed for future expansion and integration. A common expansion is the

EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate

many units in a network.

2. EOMC/CIB. Control Interface Box:

The Control Interface Box is part of the SCADA system.

Control interface box with process diagram in the front panel and with the same distribution that the

different elements located in the unit, for an easy understanding by the student.

All sensors, with their respective signals, are properly manipulated from -10V. to +10V. computer output.

Sensors connectors in the interface have different pines numbers (from 2 to 16), to avoid connection errors.

Single cable between the control interface box and computer.

The unit control elements are permanently computer controlled, without necessity of changes or

connections during the whole process test procedure.

Simultaneous visualization in the computer of all parameters involved in the process.

Calibration of all sensors involved in the process.

Real time curves representation about system responses.

Storage of all the process data and results in a file.

Graphic representation, in real time, of all the process/system responses.

All the actuators’ values can be changed at any time from the keyboard allowing the analysis about

curves and responses of the whole process.

All the actuators and sensors values and their responses are displayed on only one screen in the computer.

Shield and filtered signals to avoid external interferences.

Real time computer control with flexibility of modifications from the computer keyboard of the

parameters, at any moment during the process.

Real time computer control for pumps, compressors, heating elements, control valves, etc.

Real time computer control for parameters involved in the process simultaneously.

Open control allowing modifications, at any moment and in real time, of parameters involved in the

process simultaneously.

Three safety levels, one mechanical in the unit, another electronic in the control interface and the

third one in the control software.

3. DAB. Data Acquisition Board:

The Data Acquisition board is part of the SCADA system.

PCI Express Data acquisition board (National Instruments) to be placed in a computer slot. Bus PCI

Express.

Analog input:

Number of channels= 16 single-ended or 8 differential. Resolution=16 bits, 1 in 65536.

Sampling rate up to: 250 KS/s (kilo samples per second).

Input range (V)= 10 V. Data transfers=DMA, interrupts, programmed I/0. DMA channels=6.

Analog output:

Number of channels=2. Resolution=16 bits, 1 in 65536. Maximum output rate up to: 900KS/s.

Output range(V)= 10 V. Data transfers=DMA, interrupts, programmed I/0.

Digital Input/Output:

Number of channels=24 inputs/outputs. D0 or DI Sample Clock frequency: 0 to 100 MHz.

Timing: Number of Counter/timers=4. Resolution: Counter/timers: 32 bits.

4. EOMC/CCSOF. Computer Control +Data Acquisition+Data Management Software:

The three softwares are part of the SCADA system.

Compatible with actual Windows operating systems.

Graphic and intuitive simulation of the process in screen.

Compatible with the industry standards.

Registration and visualization of all process variables in an automatic and simultaneous way.

Flexible, open and multicontrol software, developed with actual windows graphic systems, acting

simultaneously on all process parameters.

Management, processing, comparison and storage of data.

Sampling velocity up to 250 KS/s (kilo samples per second).

Calibration system for the sensors involved in the process.

It allows the registration of the alarms state and the graphic representation in real time.

Comparative analysis of the obtained data, after the process and modification of the conditions during the

process.

Open software, allowing the teacher to modify texts, instructions. Teacher’s and student’s

passwords to facilitate the teacher’s control on the student, and allowing the access to different work levels.

This unit allows the 30 students of the classroom to visualize simultaneously all the results and the

manipulation of the unit, during the process, by using a projector or an electronic whiteboard.

5. Energy Generation Modules to be used with the Base Service Unit and Waves Generator:

5.1. EOMC-1. Floating Buoy Module:

A Floating Buoy system consists of a floating structure anchored to the seabed, which is used as the

support of a cylinder which freely floats with an upwards and downwards vertical movement,

following the waves. This cylinder slides by a central shaft joint to the immobile structure. The

relative movement of the cylinder sliding through the shaft and the fixed structured serves to

activate an energy converter which can be hydraulic or electromagnetic.

The EOMC-1 module is designed to operate with a double acting water pump that provides a

variable load and measurable output.

There are several interchangeable floats: round, triangular and rectangular bottom floats, and

another rectangular float of larger size. The floats are supplied with a support to which weights can

be added.

This module includes:

- A double acting water pump. This pump is fixed to a stainless steel frame. Pump material: PVC.

- Four interchangeable floats: a round bottom float, a triangular float, a rectangular float and

other rectangular float but larger size. Floats are made of medium density foam, and each float

is provided with support to which weights can be added.

- Set of weights: three 100 g. weight and a 50 g. weight.

- The double acting water pump extracts a variable amount of water due to the up thrust of the

wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a

support. The amount of water collected over a number of wave cycles can be measured. They

include two flow sensors to measure the impelled water flow by the Module.

The module is prepared to be installed in the Base Service Unit and Waves Generator (EOMC-UB).

5.2. EOMC-2. Oscillating Water Column Module:

An Oscillating Water Column system is a structure with an opening for the wave.

When the water enters in the enclosure, it displaces the existing air into the enclosure and forces the

air to exit by a duct where a turbine is installed. The air makes the turbine coupled to a generator to

rotate. When the wave retires, the air enters in the enclosure through the same duct, at this moment

in the reverse direction.

The EOMC-2 module allows experiments to be carried out using such a wave absorber. This

module uses the oscillating air to drive a pneumatic piston connected to a special pump that

provides an easily variable load and measurable output.

This module consists of three sections: a chamber to create the moving column of air, a pneumatic

piston and a water pump. The chamber is mounted with its open-end submerged below the water

level, in the path of the waves and creates a column of moving air. The upper edge of the chamber

is attached to a pipe ducting the air to a cylinder, in which a lightweight piston is able to move. The

energy in the wave is transferred to the air, which is in turn transferred to the piston. The piston is

connected via a straight connecting rod to the double acting water pump.

This module includes:

A double acting water pump. This pump is fixed to a stainless steel frame. Pump material: PVC.

An air chamber.

A pneumatic piston, diameter: 54.4 mm.

The double acting water pump extracts a variable amount of water due to the up thrust of the

wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a

support. The amount of water collected over a number of wave cycles can be measured. They

include two flow sensors to measure the impelled water flow by the Module.

The module is prepared to be installed in the Base Service Unit and Waves Generator (EOMC-UB).

5.3. EOMC-3. Pelamis Module:

The “Pelamis” is an attenuating type device. It consists of a longitudinal chain of cylinders linked

each one with the others and anchored to the seabed, so that they are correspondingly aligned to

the waves direction. A cylinders nodding is produced because of the wave height and this

movement is used by the pistons connected between each cylinder to impulse the fluid in an

hydraulic circuit to produce electric energy.

The EOMC-3 module consists of a longitudinal chain of two cylinders linked each other. A double

acting water pump is connected between each cylinder.

This module includes:

A double acting water pump. This pump is fixed to a stainless steel frame. Pump material: PVC.

A longitudinal chain of two cylinders linked each other. This device allows to simulate a

“Pelamis” device.

Set of weights: three 100 g. weight and a 50 g. weight.

The double acting water pump extracts a variable amount of water due to the up thrust of the

wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a

support. The amount of water collected over a number of wave cycles can be measured. They

include two flow sensors to measure the impelled water flow by the Module.

The module is prepared to be installed in the Base Service Unit and Waves Generator (EOMC-UB).

5.4. EOMC-4. Tapered Channel Module:

The Tapered Channel is a channel built on the coast in the direction of the incident wave. The

channel progressively narrows to the inside of the coast. When the wave enters the channel, it goes

to a every time less section, which makes to rise its height to enter in a tank placed at the end of the

channel.

Thus, there is water at a higher height that can be used in a turbine. Summarizing, it concentrates

the waves and guides them up a ramp into a tank, from which a turbine extracts energy.

The EOMC-4 module allows experiments to be carried out on a variety of channel configurations.

This module studies the energy in breaking waves, and allows to alter the way the waves break.

The module includes three ramps with different slop and a reservoir to contain and measure the

water.

The ramps have two walls, which can be adjusted to provide a contraction on the wave as it moves

up the ramp.

This module include:

Three ramps with different slop and adjustable walls.

A reservoir to contain and measure the water.

The module is prepared to be installed in the Base Service Unit and Waves Generator (EOMC-UB).

5.5. EOMC-5. Salter’s Duck Module:

Salter's Duck is a small buoy anchored to the seabed in a particular way which seems a duck moves

in a swinging way when receiving the waves. This rotation is used to move, by means of

mechanisms, a system connected to a generator.

The EOMC-5 module is designed to provide experiments to test the performance of basic flexible

devices. A flexible device forms a structure from which a float can pivot.

The module captures the wave's energy by using a floating device. The device is extended beyond

the pivot point by a lever used to drive the double acting water pump.

The float is supplied with a support to which weights can be added.

This module include:

A double acting water pump. This pump is fixed to a stainless steel frame. Pump material: PVC.

A flexible float.

Set of weights: three 100 g. weight and a 50 g. weight.

The double acting water pump extracts a variable amount of water due to the up thrust of the

wave and the down force of gravity. The outlet pipes are routed to two reservoirs mounted on a

support. The amount of water collected over a number of wave cycles can be measured. They

include two flow sensors to measure the impelled water flow by the Module.

The module is prepared to be installed in the Base Service Unit and Waves Generator (EOMC-UB).

6. Cables and Accessories, for normal operation.

7. Manuals:

This unit is supplied with 8 manuals: Required Services, Assembly and Installation, Interface and

Control Software, Starting-up, Safety, Maintenance, Calibration & Practices Manuals.