PL-750569

Ermapompes

Reviews

Not reviewed yet

Producer

Content languages

English

,

French

Certification labels

CE

Warranty

24

Producer product code

PO20

Industrial Maintenance

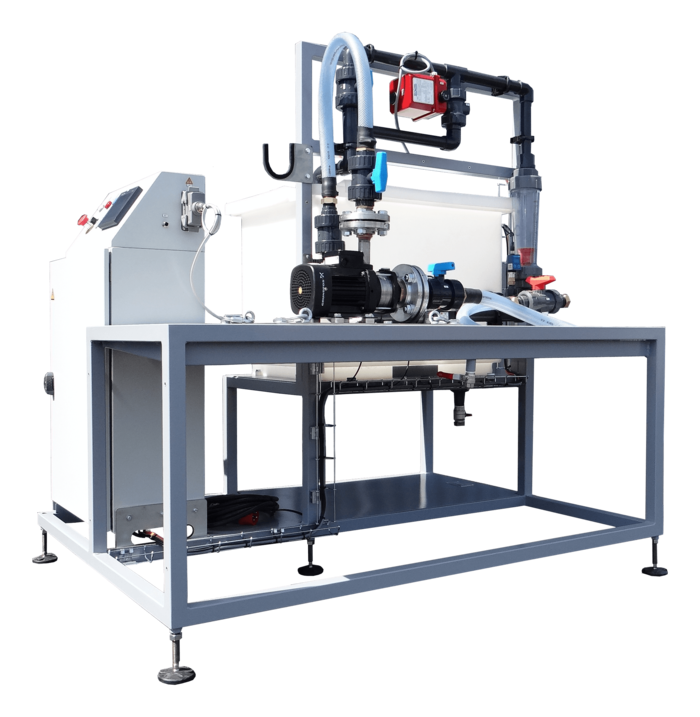

Study, maintenance and testing bench for industrial pumps

Features :

- Industrial pumps(centrifugal, lobe, sewage, etc.)

- Control valves (solenoid valves)

- Sensors and measures (flow, pressure, torque, voltage, current)

- Control and command (Webserver controller, speed drive)

Training activities:

- Functional analysis, studying the technologies used and constructive solutions (3D modeling on SolidWorks)

- Hydraulic connection, commissioning, tightness testing and pump performance testing (flow/pressure, vibration, acoustics, etc.)

- Assembly, disassembly and adjustments (e.g., Shaft alignment of standard centrifugal pump, cleaning, etc.)

- Controlling mechanical stress and heavy handling (e.g., Laying/removing pumps on/from the test bench)

- Monitoring, inspections, diagnostics, corrective maintenance and improving maintenance (Direct or speed drive) motor starter wiring

- Studying the speed drive configuration and performance

- Energy consumption and efficiency study (with / without speed drive)

- Analysis of the test device (information chain) and controller and embedded Web supervision programming

Key points:

- The product is adapted for trainings in electrotechnics, control and maintenance

- Automatic curve of the pressure/flow characteristics of industrial pumps

- Unique support for maintenance training in water-related trades and process industries

- Spare parts are supplied with each pump

- Mechanical operations can be validated through functional testing

- Multiple workstations: One test bench for several pumps

References :

- PO20 : Maintenance and tightness testing bench

- MV11 : Workshop crane (Optional)

- PO21 : Standard centrifugal pump

- PO22 : Multi stage horizontal centrifugal pump

- PO23 : Sewage pump

- PO24 : Displacement pump

- PO25 : Diaphragm dosing pump

- PO15 : Mechanical tool kit

- PO16 : Maintenance measuring tools

Technical Specifications:

- 5 industrial pumps (centrifugal, sewage, peristaltic, diaphragm dosing)

- Control valves

- Sensors and measurements (flow, pressure, torque, voltage, current)

- PLC with HMI and webserver

- Speed drive

- Automatic curve of the pressure/flow characteristics of industrial pumps

- Spare parts are supplied with each pump

- Mechanical operations can be validated through functional testing

5 industrial pumps (centrifugal, sewage, peristaltic, diaphragm dosing)

Control valves

Sensors and measurements (flow, pressure, torque, voltage, current)

PLC with HMI and webserver

Speed drive

Automatic curve of the pressure/flow characteristics of industrial pumps

Spare parts are supplied with each pump

Mechanical operations can be validated through functional testing

Voltage availability

220-240V

Production lead time

80 days

Teacher materials available

Yes

Student materials available

Yes

E-Learning modules

No

Similar products

Best products in this category

The system allows the evaluation, after each assembly and disassembly, of a set of shafts and bearin

Industrial Maintenance

Content languages

English

,

Italian

,

Spanish

PRODUCTS INTRODUCTION

This training system is designed and developed based on the AHK mechatronics

Industrial Maintenance

Content languages

German

,

English

,

Chinese

The GP Strategies® Electrical Troubleshooting Training Station is designed to introduce maintenance

Industrial Maintenance

Content languages

English

The Pump/Mechanical Training Station provides hands-on training for mechanical skills using a functi

Industrial Maintenance

Content languages

English